Model 600® Street Sweeper

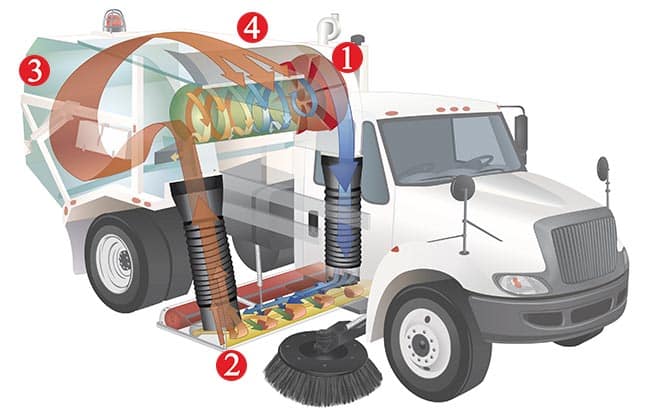

The TYMCO Model 600 is both extremely reliable and incredibly powerful. Whether you’re sweeping city streets during leaf season, cleaning up on a construction site or sweeping behind a milling machine or road reclaimer, getting the job done with the Model 600 is quick to perform and easy to operate. Not only is it built using the highly efficient, time-tested TYMCO Regenerative Air System that provides unprecedented reliability, but it also delivers incredible performance and an amazingly clean sweep.

The Model 600 is, quite simply, the sweeper that changed the industry. Before it, all sweepers were designed in one of two ways – either a mechanical main broom (100% broom sweeping) or a vacuum (which still requires a main broom for 75% of the sweeping path to transfer debris to the vacuum head).

Mechanical main brooms introduce additional expense and complexity, and vacuum sweepers, by the nature of their design, have to exhaust all air used while sweeping which can contribute to poorer air quality in harsh sweeping environments.

The Model 600 has always delivered excellent performance without a mechanical main broom or exhausting dusty air – giving you a low total cost of ownership and a more environmentally friendly sweeper.

TYMCO Sweeper Design

TYMCO Sweepers are designed in way that truly reflects the culture at TYMCO. When our engineers approach a challenge or a need on the sweeper, they work to develop straightforward solutions. For example, all TYMCO Sweepers use True Regenerative Air. This design delivers the simplest approach as well as the highest performance with the lowest downtime as compared to other sweeper technologies.

- True Regenerative Air

- Smart Gutter Broom

- Easy Access to Components

- Operator Friendly Design

- High Productivity

- Low Maintenance

More About TYMCO Sweeper Design

Features

Pick-Up Head

The TYMCO Model 600® pick-up head incorporates full-width air blast and suction and is designed to work effortlessly with the TYMCO Regenerative Air System to pick up a wide variety of street debris from light trash and leaves to heavy dirt and gravel. The Model 600 pick-up head also comes standard with long-lasting Duo-Skids® which provide increased sweeping performance and longer wear.

The Model 600 may be equipped with the optional Broom Assist Head (BAH) for applications where a broom may be desired. The BAH is controlled by the operator in the cab by a single switch allowing broom-assisted sweeping only when needed because the majority of debris is removed by the powerful TYMCO Regenerative Air System.

The large 12” diameter by 79” long broom is mounted at the rear of the BAH and is fully enclosed for optimum dust control and eliminating risk of “throwing” debris outside the sweep path. The fast rotating BAH broom provides excellent performance by automatically applying as much pressure as needed to loosen heavy, packed-on debris and projecting it into the air blast for faster sweeping.

Hopper

The Model 600 hopper capacity is over 7.3 cubic yards and ensures owners a payload of over 10,000 lbs. The TYMCO raker-assist dumping system provides smooth discharge of debris from a stationary hopper without requiring unnecessary telescopic hydraulic cylinders for hoisting, hydraulically controlled door latch assemblies, additional hydraulic door opening cylinders, grease points and safety concerns such as pinch points and overhead clearance. The 600 hopper comes standard with two easily accessible inspection doors located on both sides of the hopper.

Gutter Broom

The 43” diameter Model 600 gutter brooms remove debris from curbs, gutters and around obstacles along city streets such as parked cars and maintenance equipment. An optional tilt adjuster allows you to reach down into the deepest curbs or gutters typically found throughout city industrial and residential streets. The innovative gutter broom provides excellent performance by automatically determining the “digging” pressure needed for different debris; therefore, owners get maximum gutter broom bristle life and sweeping performance. If the gutter broom encounters an immovable object, it will automatically retract to avoid potential damage and return to the original position once the immovable object has been passed, all without intervention from the operator.

Dust Control

The Model 600 is the only street sweeper on the market with a high-efficiency centrifugal dust separator for maximum fine dust particulate separation which provides excellent dust control while using less water. TYMCO’s engineers take several aspects into account when designing for better dust control such as water nozzle design and placement, not just adding more water like other street sweepers. The Model 600 has a water capacity of up to 440 gallons which provides hours of sweeping while maintaining excellent dust control.

Power Unit

The Model 600 is powered by a 99 horsepower John Deere auxiliary engine. This engine powers all hydraulic functions through a gear driven pump and directly belt drives the blower. The lightweight aluminum alloy blower that drives the TYMCO Regenerative Air System only requires a modest amount of horsepower; therefore TYMCO’s engineers designed the Model 600 around a smaller, more fuel efficient auxiliary engine.

Blower Wheel

The Model 600 is the only street sweeper that utilizes a super-efficient aluminum alloy blower that is self-cleaning and reduces fuel consumption because of its lightweight design requiring less horsepower. The blower is designed to work with the TYMCO Regenerative Air System to both push and pull air which delivers even greater sweeping performance. The Model 600 blower has a natural rubber coating that provides maximum wear against abrasive debris.

Rear View Camera

Cities streets and roads are full of cars, maintenance equipment, signs, light poles, trees and many other objects that need to be seen when backing up.The rear view back-up camera with in-cab display allows the operator to view the area behind the Model 600 while backing up providing additional safety and peace-of-mind to both Model 600 operators and owners.Additional cameras are also available to view the pick-up head and gutter brooms.

Truck Types

Conventional

International MV607 or Freightliner M2

Cabover

Peterbilt 220 or Autocar Xpert

The cabover truck chassis allows the Model 600 to carry additional water for dust control as well as provide space for toolbox storage and maintenance tools such as shovels, rakes and brooms. The additional storage provides more versatility if other maintenance tasks need to be taken care of after sweeping such as tending to municipal parks or other city landscaping.

Options

Operator Friendly & Productivity

Broom Assist Pick-Up Head (BAH)

The Model 600 may be equipped with the optional Broom Assist Head (BAH) for applications where a broom may be desired. The BAH is controlled by the operator in the cab by a single switch allowing broom-assisted sweeping only when needed because the majority of debris is removed by the powerful TYMCO Regenerative Air System. The large 12” diameter by 79” long broom is mounted at the rear of the BAH and is fully enclosed for optimum dust control and eliminating risk of “throwing” debris outside the sweep path. The fast rotating BAH broom provides excellent performance by automatically applying as much pressure as needed to loosen heavy, packed-on debris and projecting it into the air blast for faster sweeping.

The BAH offers independent suspension of each broom end which provides longer broom bristle life and reduces the broom “coning effect” relative to the surface being swept. TYMCO’s simple design approach allows for BAH broom replacement in 30 minutes or less and without the need to remove the pick-up head.

Gutter Broom Tilt Adjuster – Left, Right or Twin

The gutter broom tilt adjuster uses in-cab controls to adjust the gutter broom to the pitch of the surface being swept. The deepest curbs or gutters along streets and highways are no challenge when your Model 600’s gutter brooms are equipped with tilt adjusters.

Drop Down Gutter Brooms

Allows for the gutter brooms to "drop down" in front of the pick-up head so the metal bristles can scrub up extremely packed on material. Also allows very tight sweeping of curb lines to minimize amount of dust being kicked up before it is swept by the pick-up head.

Hopper Deluge System

The Hopper Deluge System is a high volume water system designed to expedite flushing of the hopper after sweeping.

Stainless Steel Hopper

For maximum corrosion and salt spray resistance, all hopper body sheets as well as the hopper screen are fabricated with low carbon, high chrome stainless steel.Stainless steel bolt-on blower housing, dust separator and hopper drain are also available.

Variable Speed Gutter Brooms

Allows the gutter broom speed to be controlled from inside the cab to adjust the broom speed to the type of debris being swept; for example, slowing the brooms down in extremely dusty environments to reduce the amount of ambient dust being kicked up.

Pick-Up Head Curtain Lifter

Hydraulic actuated and retractable roller assembly that provides the pick-up head with the ability to sweep large volume of light debris. Electronically controlled in cab.

Auxiliary Hand Hose

The auxiliary hand hose is a powerful suction nozzle for hard-to-reach cleaning such as storm drain catch basins, sumps, fence lines and around other tight areas such as dumpsters and containers.

An optional hydraulic boom assist is also available which makes operation even easier for cleaning out catch basins and sumps.

From the stowed position on the back of the sweeper, the auxiliary hand hose quickly adapts the Model 600 into a powerful suction nozzle for hard to get to cleaning applications.

The auxiliary hand hose is 8" in diameter and available with multiple nozzle extensions to reach the deepest storm drain catch basins.

Alternative Fuel

CNG

In our continuing commitment to environmentally conscious sweeping, TYMCO offers a CNG (Compressed Natural Gas) alternative fuel option for the Model 600. The Model 600 CNG option is available as a Dedicated Unit, where both the sweeper and the truck chassis are CNG powered.

Airport Applications

Lateral Airflow Nozzle (LAN)

In situations where debris needs to be cleared from runways and taxiways as quickly as possible, the TYMCO Lateral Airflow Nozzle (LAN) allows the Model 600® operator to use a high velocity, controlled air blast to clear debris such as sand, snow and grass clippings off of paved surfaces back into greenspace.

The LAN diverts air from the blower to a nozzle mounted on the left hand side of the sweeper behind the truck cab. The LAN opening can be adjusted and rotated 360 degrees for air blast positioning and switching from sweeping to the Lateral Airflow Nozzle is all controlled from within the cab.

Liquid Recovery System (LRS)

The Liquid Recovery System (LRS) allows the Model 600 to be used for recovery of standing liquids such as glycol that can accumulate around aircraft on aprons or staging areas. With increased environmental regulations on airports in regards to glycol entering stormwater runoff, airport administrators need to have a system in place for glycol recovery.

The TYMCO LRS allows the Model 600 to become even more versatile by making it a multipurpose machine – a machine for both sweeping and glycol recovery. The LRS has a liquid level sensor with a light on the control panel that indicates when the sweeper is full of over 700 gallons of glycol or other deicing fluid.

The LRS assists in pumping off liquid that was recovered while leaving any solids such as sand in the hopper for dumping. A pump is also available to facilitate removal of glycol to a suitable storage location or evacuation tanker for disposal.

Magnet Assembly

The truck chassis mounted magnet assembly comes with in-cab controls for raising and lowering the magnet to the paved surface. The magnet is self-cleaning and comes in standard duty and heavy duty gauss strengths for removal of lighter or heavier ferrous metals.

Street Sweeping & The Environment

The Model 600 has several environmental benefits, features, and options including:

- Doing More With Less

- Water Efficiency

- South Coast AQMD Rule 1186 Certification

- Compressed Natural Gas (CNG)

Photo Gallery

Video Gallery

Model 600 Regenerative Air Sweeper® Specs

Diesel Auxiliary Engine / Diesel Conventional Cab Chassis

Download PDFSweeper Auxiliary Engine

- Engine - John Deere 4045 turbo FT4, 4 cyl.

- Displacement - 275 in3 (4.5 L)

- Power - 99 HP @ 2200 RPM (74 kW)

- Net torque - 315 lb-ft @ 1600 RPM (427 Nm)

- Air cleaner - Heavy duty, w/pre-cleaner, scavenge vacuum hose, and in-cab air restriction indicator w/gauge.

- Remote oil filter - Spin on, full flow

- Auxiliary engine fuel tank shared with chassis

- Diesel fuel tank capacity - 51 gal (193 L)

-

DEF tank - Dedicated

- Capacity (volumetric) - 5.4 gal (20.6 L)

- Capacity (useable) - 3.8 gal (14.4 L)

- Auxiliary engine protection system

- Fuel/water separator with WIF sensor

- Fuel filters - 10 μm primary, 2 μm secondary

- Open crankcase ventilation (OCV) filter

Blower, Rubber Coated

- Aluminum alloy high volume, open face turbine

- Bearings - (2) sealed lifetime lube, anti-friction

- Bolt-on housing - Steel w/abrasion resistant, replaceable liner

- Drive - Heavy duty power band

Dust Separator, Rubber Lined, High Capacity

- Type - Cyclonic, multipass, centrifugal separation

- Size - 20 x 61 in cylindrical area (51 x 155 cm)

- Located adjacent to blower within hopper

- Particulate removal achieved through 61 in (155 cm) skimmer slot into skimmer hood

- Separator door opened from hopper exterior

- Abrasion resistant housing w/replaceable wear resistant liner

Hopper

- Capacity (volumetric) - 7.3 yd3 (5.6 m3)

- Capacity (useable) - 6 yd3 (4.6 m3)

- Construction - Welded steel plate with integral stiffeners

- Floor angle - 22°

- Dump door opening - 84 x 44 in (213 x 112 cm)

- Dump method - Hydraulic with raker bar

- Dump direction – Rear

- Dumping height - 36 in (91.5 cm)

- Inspection doors – (1) Each side of hopper, 9.75 x 29 in (25 x 73.5 cm)

Pick-Up Head

- Type - Dual chamber

- Width (inside dimension) - 87 in (221 cm)

- Pick-up head area - 2610 in2 (1.68 m2)

- Suspension - (4) springs, (2) drag links

- Skids - DUO SKID®, long-life carbide

- Suction hose diameter - 14 in (35.5 cm)

- Pressure hose diameter - 14 in (35.5 cm)

- Pressure bleeder - Cable operated

- Reverse pick-up head system

Gutter Broom, Twin, Patented

- Drive - Constant speed non-reversible hydraulic motor

- Adjustment - Adjustable for down pressure, pattern and wear

- Down pressure - Automatic

- Flexibility - Integral anti-damage "swing away" relief valve

- Broom - 43 in dia. (109 cm) steel wire, vertical digger

- Floodlights – (2) LED

- Parabolic mirrors – (2) 10.5 in (26.67 cm) dia.

Hydraulic System

- Operates gutter broom(s), dump and pick-up head

- Drive - Gear driven from auxiliary engine

- Flow rate - 8 GPM (30.3 LPM)

- Reservoir - 25 gal (94.6 L) w/80 mesh suction strainer, sight/temperature gauge

- Return filter - 3 μm in-line

- Vent Filter - 10 μm spin-on

- Hydraulic oil – Extended life 10W ISO 46

- Hydraulic temperature shutdown system w/temperature gauge in cab

Dust Control System

- Water spray nozzles for dust suppression

- Pump - Electric diaphragm

- Reservoirs - Polyethylene 220 gal (833 L) total minimum

- Filter - 80 mesh in-line

- Low water shut-off - Safety shut-off with audible and visual indicator in cab

-

Spray nozzles:

- Around pick-up head - 4

- Gutter brooms (each) - 2

- Hopper (inside) - 1

- Hydrant fill hose w/storage area - 20 ft (6 m)

Control System

-

BlueLogic® Control System

Multiplexed electrical system includes hardware and TYMCO designed software that integrates the in-cab controls to the auxiliary engine and all sweeper functions; as well as provides intelligent safety features and on-board diagnostics (OBD) for the auxiliary engine and sweeper through the BlueLogic display. -

BlueLogic Display

Pedestal mounted touchscreen display provides sweeper and auxiliary engine data and includes hour meters (trip and total) for the auxiliary engine, gutter brooms, pick-up head, blower, water pump, and BAH broom if applicable; sweeper odometer (records curb miles swept and sweeping hours), service reminders, custom reminders, overspeed warning, low water audible alarm, dust control system winterization guide, and OBD. -

Interior Components

Pressure bleeder control, BlueLogic display, auxiliary fuse panel, illuminated control switches: pick-up head, gutter brooms, auxiliary engine RPM, dust control water system nozzles, safety lights. -

Exterior Components

Dump switch, BlueLogic Control Module (BCM)

Safety/Warning Devices

- Alternating LED rear flashers (2)

- Rear view camera system

- Back-up alarm

- SAE Class 1/California Title 13 amber beacon light with limb guard – LED

Optional Equipment

- AOD water pump w/washdown hose/spray gun

- Abrasion protection package

- Additional camera views - pick-up head, left gutter broom, right gutter broom

- Auto Sweep Interrupt (ASI)

- Auxiliary hand hose 8 in dia. (20 cm)

- Auxiliary hand hose hydraulic boom assist

- Auxiliary hand hose catch basin cleaning package

- Auxiliary hydraulic system

-

Broom Assist Pick-up Head (BAH®)

- Pick-up head area - 3567 in2 (2.3 m2)

- COMDEX (extra water and tool box) 330 gal (1249 L) total capacity

- Gutter broom tilt adjuster(s) (right, left or twin)

- Gutter broom variable speed

- Gutter broom drop-down

- Hi/Low pressure washdown system

- High output water system

- Hopper deluge system

- Hopper drain system

- Lateral airflow nozzle

- Linear actuator - pressure bleeder w/gauge

- Liquid recovery system

- Low emissions package (required for South Coast AQMD Rule 1186)

- Magnet: light, standard, or heavy duty

- Pick-up head curtain lifter

- Pick-up head deluge

- Shop air purge, dust control system

- Spark resistant skids

-

Stainless steel (non-magnetic) options:

-

Hopper:

- Hopper weldment

- Dump door

- Inspection doors

- Raker plate

- High capacity dust separator

- Hopper screen - Blower housing

- Hopper drain

-

Hopper:

- Paint color (other than TYMCO standard white)

Special options are available for your individual requirements. Contact your local dealer or TYMCO.

Conventional Cab Chassis Available

- International MV607

- Freightliner M2-106

Updated: 06/06/2024

Diesel Auxiliary Engine / Diesel Cabover Chassis

Download PDFSweeper Auxiliary Engine

- Engine - John Deere 4045 turbo FT4, 4 cyl.

- Displacement - 275 in3 (4.5 L)

- Power - 99 HP @ 2200 RPM (74 kW)

- Net torque - 315 lb-ft @ 1600 RPM (427 Nm)

- Air cleaner - Heavy duty, w/pre-cleaner, scavenge vacuum hose, and in-cab air restriction indicator w/gauge.

- Remote oil filter - Spin on, full flow

- Auxiliary engine fuel tank shared with chassis engine

- Diesel fuel tank capacity - 51 gal (193 L)

-

DEF tank - Dedicated

- Capacity (volumetric) - 5.4 gal (20.6 L)

- Capacity (useable) - 3.8 gal (14.4 L)

- Auxiliary engine protection system

- Fuel/water separator with WIF sensor

- Fuel filters - 10 μm primary, 2 μm secondary

- Open crankcase ventilation (OCV) filter

Blower, Rubber Coated

- Aluminum alloy, high volume, open face turbine

- Bearings - (2) sealed lifetime lube, anti-friction

- Bolt-on housing - Steel, w/abrasion resistant, replaceable liner

- Drive - Heavy duty power band

Dust Separator, Rubber Lined, High Capacity

- Type - Cyclonic, multipass, centrifugal separation

- Size - 20 x 61 in cylindrical area (51 x 155 cm)

- Located adjacent to blower within hopper

- Particulate removal achieved through 61 in (155 cm) skimmer slot into skimmer hood

- Separator door opened from hopper exterior

- Abrasion resistant housing w/ replaceable wear resistant liner

Hopper

- Capacity (volumetric) - 7.3 yd3 (5.6 m3)

- Capacity (useable) - 6 yd3 (4.6 m3)

- Construction - Welded steel plate with integral stiffeners

- Floor angle - 22°

- Dump door opening - 84 x 44 in (213 x 112 cm)

- Dump method - Hydraulic with raker bar

- Dump direction – Rear

- Dump height - 36 in (91.5 cm)

- Inspection doors – (1) Each side of hopper, 9.75 x 29 in (25 x 73.5 cm)

Pick-Up Head

- Type - Dual chamber

- Width (inside dimension) - 87 in (221 cm)

- Std. Pick-up head area - 2610 in2 (1.68 m2)

- Suspension - (4) springs, (2) drag links

- Skids - DUO SKID®, long-life carbide

- Suction hose diameter - 14 in (35.5 cm)

- Pressure hose diameter - 14 in (35.5 cm)

- Linear actuator - pressure bleeder w/gauge

- Reverse pick-up head system

Gutter Broom, Twin, Patented

- Drive - Constant speed non-reversible hydraulic motor

- Adjustment - Adjustable for down pressure, pattern and wear

- Down pressure - Automatic

- Flexibility - Integral anti-damage “swing away” relief valve

- Broom - 43 in dia. (109 cm) steel wire, vertical digger

- Floodlights – (2) LED

- Parabolic mirrors – (2) 10.5 in (26.67 cm) dia.

Hydraulic System

- Operates gutter broom(s), dump and pick-up head

- Drive - Gear driven from auxiliary engine

- Flow rate - 8 GPM (30.3 LPM)

- Reservoir - 25 gal (94.6 L) w/80 mesh suction strainer, sight/temperature gauge

- Cooler - Air to oil, integral with auxiliary engine heat exchanger

- Return filter - 3 μm in-line

- Vent Filter - 10 μm spin-on

- Hydraulic oil – Extended life 10W ISO 46

- Hydraulic temperature shutdown system w/temperature gauge in cab

Dust Control System

- Water spray nozzles for dust suppression

- Pump - Electric diaphragm

- Reservoirs - Polyethylene 330 gal (1249 L) total minimum

- Filter - 80 mesh in-line

- Low water shut-off - Safety shut-off with audible and visual indicator in cab

-

Spray nozzles:

- Around pick-up head - 4

- Gutter brooms (each) - 2

- Hopper (inside) - 1

- Hydrant fill hose w/storage area - 20 ft (6 m)

Control System

-

BlueLogic® Control System

Multiplexed electrical system includes hardware and TYMCO designed software that integrates the in-cab controls to the auxiliary engine and all sweeper functions; as well as provides intelligent safety features and on-board diagnostics (OBD) for the auxiliary engine and sweeper through the BlueLogic display. -

BlueLogic Display

Pedestal mounted touchscreen display provides sweeper and auxiliary engine data and includes hour meters (trip and total) for the auxiliary engine, gutter brooms, pick-up head, blower, water pump, and BAH broom if applicable; sweeper odometer (records curb miles swept and sweeping hours), service reminders, custom reminders, overspeed warning, low water audible alarm, dust control system winterization guide, and OBD. -

Interior Components

BlueLogic display, auxiliary fuse panel, illuminated control switches: pick-up head, gutter brooms, auxiliary engine RPM, pressure bleeder, dust control water system nozzles, safety lights. -

Exterior Components

Dump switch, BlueLogic Control Module (BCM)

Safety/Warning Devices

- Alternating LED rear flashers (2)

- Rear view camera system

- Back-up alarm

- SAE Class 1/California Title 13 amber beacon light with limb guard – LED

Optional Equipment

- AOD water pump w/washdown hose/spray gun

- Abrasion protection package

- Additional camera views - pick-up head, left gutter broom, right gutter broom

- Auto Sweep Interrupt

- Auxiliary hand hose 8 in dia. (20 cm)

- Auxiliary hand hose hydraulic boom assist

- Auxiliary hand hose catch basin cleaning package

- Auxiliary hydraulic system

-

Broom Assist Pick-up Head (BAH®)

- Pick-up head area - 3567 in2 (2.3 m2)

- Extra water capacity - 440 gal (1665 L) total (Peterbilt 220 only)

- Gutter broom tilt adjuster(s) (right, left or twin)

- Gutter broom variable speed

- Gutter broom drop-down

- Hi/Low pressure washdown system

- High output water system

- Hopper deluge system

- Hopper drain system

- Lateral airflow nozzle

- Liquid recovery system

- Low emissions package (required for South Coast AQMD Rule 1186)

- Magnet: light, standard, or heavy duty

- Pick-up head curtain lifter

- Pick-up head deluge

- Shop air purge, dust control system

- Spark resistant skids

-

Stainless steel (non-magnetic) options:

-

Hopper:

- Hopper weldment

- Dump door

- Inspection doors

- Raker plate

- High capacity dust separator

- Hopper screen - Blower housing

- Hopper drain

-

Hopper:

- Paint color (other than TYMCO standard white)

Special options are available for your individual requirements. Contact your local dealer or TYMCO.

Cabover Chassis Available

- Peterbilt 220

- Autocar Xpert

Updated: 06/06/2024

CNG Auxiliary Engine/CNG Chassis

Download PDFSweeper Auxiliary Engine

- Engine - KEM/GM Vortec 5700 CNG

- Displacement - 350 in3 (5.7 L)

- Power - 124 HP @ 2400 RPM (92 kW)

- Net torque - 284 lb-ft @ 2100 RPM (385 Nm)

- Air cleaner - Heavy duty, w/pre-cleaner, scavenge vacuum hose, and in-cab air restriction indicator w/gauge.

- Oil filter - Spin on, full flow

- Auxiliary engine fuel rack shared with chassis engine

- CNG fuel rack capacity - 60 DGE (227 DLE)

- Auxiliary engine shutdown system

Blower, Rubber Coated

- Aluminum alloy high volume, open face turbine

- Bearings - (2) sealed lifetime lube, anti-friction

- Bolt-on housing - Steel w/abrasion resistant, replaceable liner

- Drive – Heavy duty power band

Dust Separator, Rubber Lined, High Capacity

- Type - Cyclonic, multipass, centrifugal separation

- Size - 20 x 61 in cylindrical area (51 cm x 155 cm)

- Located adjacent to blower within hopper

- Particulate removal achieved through 61 in (155 cm) skimmer slot into skimmer hood

- Separator door opened from hopper exterior

- Abrasion resistant housing w/ replaceable wear resistant liner

Hopper

- Capacity (volumetric) - 7.3 yd3 (5.6 m3)

- Capacity (useable) - 6 yd3 (4.6 m3)

- Construction - Welded steel plate with integral stiffeners

- Floor angle - 22°

- Dump door opening - 84 x 44 in (213 mm x 112 cm)

- Dump method - Hydraulic with raker bar

- Dump direction – Rear

- Dump height - 36 in (91.5 cm)

- Inspection doors – (1) Each side of hopper, 9.75 x 29 in (25 x 73.5 cm)

Pick-Up Head

- Type - Dual chamber

- Width (inside dimension) - 87 in (221 cm)

- Pick-up head area - 2610 in2 (1.68m2)

- Suspension - (4) springs, (2) drag links

- Skids - DUO-SKID®, long-life carbide

- Suction hose diameter - 14 in (35.5 cm)

- Pressure hose diameter - 14 in (35.5 cm)

- Pressure bleeder - Cable operated

- Reverse pick-up head system

Gutter Broom, Twin, Patented

- Drive - Constant speed non-reversible hydraulic motor

- Adjustment - Adjustable for down pressure, pattern and wear

- Down pressure - Automatic

- Flexibility - Integral anti-damage "swing away" relief valve

- Broom - 43 in dia. (109 cm) steel wire, vertical digger

- Floodlights – (2) LED

- Parabolic mirrors – (2) 10.5 in (26.67 cm) dia.

Hydraulic System

- Operates gutter broom(s), dump and pick-up head

- Drive - Belt driven from auxiliary engine

- Flow rate - 8 GPM (30.3 LPM)

- Reservoir - 25 gal (94.6 L) w/ 80 mesh suction strainer, sight/temperature gauge

- Cooler - Air to oil

- Return filter - 3 μm in-line

- Vent Filter - 10 μm spin-on

- Hydraulic oil – Extended life 10W ISO 46

- Hydraulic temperature shutdown system w/temperature gauge in cab

Dust Control System

- Water spray nozzles for dust suppression

- Pump - Electric diaphragm

- Pump - Electric diaphragm or air diaphragm

- Reservoirs - Polyethylene 220 gal (833 L) total minimum

- Filter - 80 mesh in-line

- Low water shut-off - Safety shut-off with audible and visual indicator in cab

-

Spray nozzles:

- Around pick-up head – 4

- Gutter brooms (each) – 2

- Hopper (inside) – 1

- Hydrant fill hose w/ storage area - 20 ft (6 m)

Control System

-

BlueLogic® Control System

Multiplexed electrical system includes hardware and TYMCO designed software that integrates the in-cab controls to the auxiliary engine and all sweeper functions; as well as provides intelligent safety features and on-board diagnostics (OBD) for the auxiliary engine and sweeper through the BlueLogic display. -

BlueLogic BlueLogic Display

Pedestal mounted touchscreen display provides sweeper and auxiliary engine data and includes hour meters (trip and total) for the auxiliary engine, gutter brooms, pick-up head, blower, water pump, and BAH broom if applicable; sweeper odometer (records curb miles swept and sweeping hours), service reminders, custom reminders, overspeed warning, low water audible alarm, dust control system winterization guide, and OBD. -

Interior Components

Pressure bleeder control, BlueLogic display, auxiliary fuse panel, illuminated control switches: pick-up head, gutter brooms, auxiliary engine RPM, dust control water system nozzles, safety lights. -

Exterior Components

Dump switch, BlueLogic Control Module (BCM)

Safety/Warning Devices

- Alternating LED rear flashers (2)

- Rear view camera system

- Back-up alarm

- SAE Class 1/California Title 13 amber beacon light with limb guard - LED

Optional Equipment

- AOD water pump w/ washdown hose/spray gun

- Abrasion protection package

- Additional camera views - pick-up head, left gutter broom, right gutter broom

- Auto Sweep Interrupt (ASI)

- Auxiliary hand hose 8 in dia. (20 cm)

- Auxiliary hand hose hydraulic boom assist

- Auxiliary hand hose catch basin cleaning package

- Auxiliary hydraulic system

-

Broom Assist Pick-up Head (BAH®)

- Pick-up head area - 3567 in2 (2.3 m2)

- COMDEX (extra water and tool box) 330 gal (1249 L) total capacity (171" WB Autocar chassis only)

- Gutter broom tilt adjuster(s) (right, left, or twin)

- Gutter broom variable speed

- Gutter broom drop-down

- High output water system

- Hopper deluge system

- Hopper drain system

- Lateral airflow nozzle

- Linear actuator - pressure bleeder w/gauge (Standard on cabover chassis)

- Liquid recovery system

- Low emissions package (required for South Coast AQMD Rule 1186, not applicable with high output water system)

- Magnet: light, standard, or heavy duty

- Pick-up head curtain lifter

- Pick-up head deluge

- Shop air purge, dust control system

- Spark resistant skids

-

Stainless steel (non-magnetic) options:

-

Hopper:

- Hopper weldment

- Dump door

- Inspection doors

- Raker plate

- High capacity dust separator

- Hopper screen - Blower housing

- Hopper drain

-

Hopper:

- Paint color (other than TYMCO standard white)

Special options are available for your individual requirements. Contact your local dealer or TYMCO.

Chassis Available

- Freightliner M2-112 CNG - 176 in wheelbase

- Autocar Xpert CNG - 157 in wheelbase

- Autocar Xpert CNG – 171 in wheelbase (COMDEX)

Updated: 06/06/2024