TYMCO OEM Replacement Parts for Sweepers

Don’t Downgrade a Superior Product by Using Inferior Replacement Parts

Original Equipment Manufacturer

The Difference is Long Term Performance

TYMCO is aware that many “Will-Fit” companies make themselves well known to our customers offering cutrate pricing on so called crossover replacement parts with claims that their parts are of equal design and quality. This is especially prevalent in the area of wear items such as pick-up head curtains, gutter broom bristles, skid plates, blowers and suction/pressure hoses. However, in most cases, the nonstandard parts are also sub-standard and premature failure and/or poor performance is the end result. The reality of this is that the saving of a dime usually results in the waste of a dollar in the long run where “Will-Fit” parts are concerned.

Pick-up Head Curtains

We have received many complaints over the years concerning sweeping performance deficiencies only to discover that non-standard “Will-Fit” curtains had been installed on the sweeper. The curtains were subsequently changed to TYMCO OEM curtains and the problem immediately disappeared.

Many hours of exhaustive research and testing have gone into developing a very stringent specification for TYMCO curtains to achieve the exact tensile strength, durometer hardness range, rigidity and material composition along with multiple plys of fabric for additional strength. This combination provides maximum performance and wear properties under all surface conditions and climate variances.

Blower Wheel

TYMCO blower wheels are cast of high grade (no re-melt) aluminum alloy in a permanent mold. The sand molding method used by most “Copy Cat” companies produces a rough, porous finish with less density than a part produced in a permanent mold. Both the inside and outside diameters of the TYMCO blowers are Computer Numerical Controlled (CNC) machined to produce perfect concentricity and precise tolerances.

The TYMCO rubber lined coated blower has a hand-laid high-quality natural rubber coating bonded to each paddle to produce longevity that far exceeds after-market blowers. Only a natural rubber coating on any sweeper blower wheel will greatly extend its life. Beware of “long-life” claims in abrasive conditions without it.

The TYMCO blower wheel design (which has not been duplicated in the field by any “Will-Fit” company or manufacturer) produces a GREATER VOLUME of air flow through the sweeper. The auxiliary engine RPM can actually be lowered and still have superior sweeping performance allowing the sweeper to run more quietly, saving fuel and wear-and-tear on the auxiliary engine.

Safety

TYMCO is aware of several cases where aftermarket blowers have literally disintegrated when accelerated to operating RPM due to poor quality of the casting and/or improper balancing. When this occurs, the supposed savings become very insignificant compared to the cost of repairs and downtime.

Longevity

The wear life on aftermarket blowers is usually 50% of a TYMCO blower. With that in mind, what becomes of the 15-20% savings up front? The TYMCO designed blower configuration has increased performance and wear life and has not been duplicated in the field simply because in order to accomplish what TYMCO has done requires extensive engineering and investment.

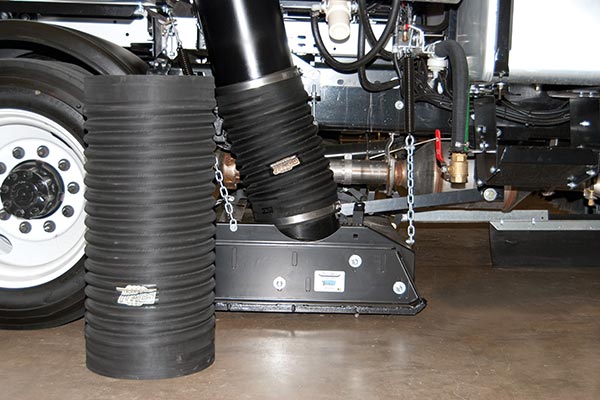

Suction / Pressure Hoses

TYMCO suction and pressure hoses are made of high grade materials suitable for severe applications. The heavy-duty suction hose, because of its exposure to all debris being swept, is of a multiple-ply design with a 5/16 inch abrasion resistant rubber inner liner, plys of nylon fabric reinforcement and a 5/64 inch neoprene rubber outer cover.

The clamping points, or cuffs, have an extra 3/16 inch layer of rubber and an additional ply of nylon. TYMCO pressure hoses, while providing long life, are made of 100% urethane designed to withstand temperature variances and abrasion with no fabric included.

Gutter Broom

Feedback from the field has proven that the same short life problem holds true concerning gutter broom bristles purchased from “Will-Fit” companies. Our vertical digger filler elements are of high carbon, patented wire. This type of high quality material and construction gives gutter brooms significantly longer life in everyday applications.

BAH® Broom

The TYMCO Broom Assist Head (BAH) standard rotary broom is constructed of virgin polypropylene bristles, each having a diameter of .078 and forming a 12 inch diameter around a schedule 40 pipe. Unlike “will-fit” brooms, every TYMCO BAH broom comes with a new bronze hub helping deliver excellent performance every time. Will-fit” brooms either do not come with a new hub or may come with a weaker plastic hub.

Duo-Skid®

TYMCO skid plates are manufactured through a unique and patented technology using a foundry process whereby molten steel is poured around preformed Kennametal® carbide inserts. The result is a part with the excellent abrasion resistance of carbide and the ductility (resistance to breakage) and weldability of steel. This process produces skids with very uniform, evenly spaced carbide inserts positioned closely together.

The patented molten steel poured around these inserts is air hardened to a Brinell hardness in the 500-600 range. Competitors using the brazed or button type skids must use relativity soft, low carbon steel (225-230 Brinell hardness) to insure adequate brazing or provide machineability for the button type. This soft steel and inconsistent spacing results in:

- Loss of the pick-up head’s air tight seal due to wear gaps.

- Significant reduction in sweeping performance.

- The loss of the inserts themselves.

However, the TYMCO designed skid plate lends itself to very evenly distributed wear along the full length of the skid, plus the fact that a TYMCO DUO-SKID® is reversible. Should uneven wear be experienced due to misadjustment of the skid plates or flotation springs, the skid plates can simply be reversed and adjusted making it possible to realize 100% wear life on each. Many users have experienced in excess of three years of wear on one set and are still going! Our confidence in the TYMCO DUO-SKIDS is evidenced by our two year warranty.