Model 500x® High Dump Street Sweeper

The TYMCO Model 500x® truly is refined perfection. We took the best of the Model 600® – unprecedented reliability and incredible power – and integrated cutting edge multiplex electronics and the industry’s highest dumping hopper lift assembly to build the most advanced high dump street sweeper available today.

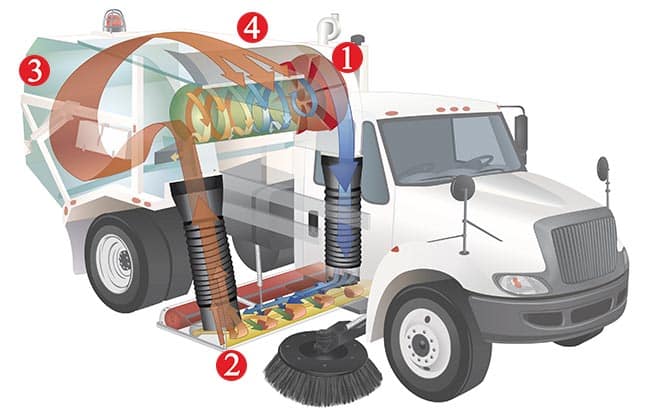

Whether you’re sweeping state highways, city streets or sweeping behind a milling machine or road reclaimer, any successful high dump sweeping program needs a reliable sweeper. The Model 500x is built using the high-efficiency, time-tested TYMCO Regenerative Air System that delivers rock-solid reliability and an amazingly clean sweep.

With a fast dump cycle of less than 68 seconds and a soaring 11 foot dump height, the Model 500x provides more versatility than any other high dump street sweeper on the market.

TYMCO Sweeper Design

TYMCO Sweepers are designed in way that truly reflects the culture at TYMCO. When our engineers approach a challenge or a need on the sweeper, they work to develop straightforward solutions. For example, all TYMCO Sweepers use True Regenerative Air. This design delivers the simplest approach as well as the highest performance with the lowest downtime as compared to other sweeper technologies.

- True Regenerative Air

- Smart Gutter Broom

- Easy Access to Components

- Operator Friendly Design

- High Productivity

- Low Maintenance

More About TYMCO Sweeper Design

Features

Broom Assist Pick-Up Head

The TYMCO Model 500x® is equipped with the Broom Assist Head (BAH) which incorporates full-width air blast and suction and is designed to work effortlessly with the TYMCO Regenerative Air System to pick up a wide variety of street debris from light trash and leaves to heavy dirt and gravel. The BAH is controlled by the operator in the cab by a single switch allowing broom-assisted sweeping only when needed because the majority of debris is removed by the powerful TYMCO Regenerative Air System.

The large 12” diameter by 79” long broom is mounted at the rear of the BAH and is fully enclosed for optimum dust control and eliminating risk of “throwing” debris outside the sweep path. The fast rotating BAH broom provides excellent performance by automatically applying as much pressure as needed to loosen heavy, packed-on debris and projecting it into the air blast for faster sweeping.

The BAH offers independent suspension of each broom end which provides longer broom bristle life and reduces the broom “coning effect” relative to the surface being swept. TYMCO’s simple design approach allows for BAH broom replacement in 30 minutes or less and without the need to remove the pick-up head.

The Model 500x pick-up head also comes standard with long-lasting Duo-Skids® which provide increased sweeping performance and longer wear.

Hopper and Chute

The Model 500x hopper capacity is over 5.7 cubic yards and ensures owners a payload of over 6000 lbs. All 500x hopper body sheets as well as the hopper screen are fabricated with low carbon, high chrome stainless steel providing additional longevity and easier cleanout of the hopper.

A variable dump height from 2 feet to 11 feet allows dumping into various size and type containers. The large hopper door allows easy dumping and is hydraulically and mechanically locked for an air and watertight seal.

The large stainless steel discharge chute project debris provides smooth discharge of debris into the middle of the dump container without the need of a hopper side shift. The chute is designed to float 45 degrees upward, preventing major damage should it come in contact with the debris container.

Hopper Lift Assembly

Has a 10,000 lb lift capacity. All pivots on the lift are self-lubricating and never require greasing. Integral counterbalance holding valves ensure controlled lowering of the lift assembly and serve as redundant safety locks. Dual stabilizers automatically deploy before the dump cycle begins assuring unit stability throughout the dumping procedure. The 500x is also integrated with the truck chassis transmission, only allowing dumping when the truck is in neutral with the parking break set.

Gutter Broom

The 43” diameter Model 500x gutter brooms remove debris from curbs, gutters and around obstacles along city streets such as parked cars and maintenance equipment.

An optional tilt adjuster allows you to reach down into the deepest curbs or gutters typically found throughout city industrial and residential streets. The innovative gutter broom provides excellent performance by automatically determining the “digging” pressure needed for different debris; therefore, owners get maximum gutter broom bristle life and sweeping performance. If the gutter broom encounters an immovable object, it will automatically retract to avoid potential damage and return to the original position once the immovable object has been passed, all without intervention from the operator.

Dust Control

The Model 500x is the only street sweeper on the market with a high-efficiency centrifugal dust separator for maximum fine dust particulate separation which provides excellent dust control while using less water.

TYMCO’s engineers take several aspects into account when designing for better dust control such as water nozzle design and placement, not just adding more water like other street sweepers. For example, if the operator has not engaged the blower, but the dust control system is on, the 500x “pauses” the dust control system until the operator engages the blower; therefore saving gallons of water that could have been wasted when the operator wasn’t sweeping.

The Model 500x has a water capacity of 250 gallons which provides hours of sweeping while maintaining excellent dust control.

Power Unit

The Model 500x is powered by a 115 horsepower John Deere auxiliary engine. This engine powers the blower and all hydraulic functions through three direct driven hydraulic pumps. TYMCO’s engineers designed the Model 500x with a single speed auxiliary engine; therefore reducing wear on the engine and conserving fuel by maintaining a constant speed.

Blower Wheel

The Model 500x is the only high dump street sweeper that utilizes a super-efficient aluminum alloy blower that is self-cleaning and reduces fuel consumption because of its lightweight design requiring less horsepower. The blower is designed to work with the TYMCO Regenerative Air System to both push and pull air which delivers even greater sweeping performance. The Model 500x blower has a natural rubber coating that provides maximum wear against abrasive debris.

Rear View Camera

Cities, streets, and roads are full of cars, maintenance equipment, signs, light poles, trees and many other objects that need to be seen when backing up. The rear view back-up camera with in-cab display allows the operator to view the area behind the Model 500x while backing up providing additional safety and peace-of-mind to both Model 500x operators and owners. Additional cameras are also available to view the pick-up head and gutter brooms.

Truck Types

Conventional

International MV607 or Freightliner M2

Cabover

Peterbilt 220

Options

Magnet Assembly

The truck chassis mounted magnet assembly comes with in-cab controls for raising and lowering the magnet to the paved surface. The magnet is self-cleaning and comes in standard duty and heavy duty gauss strengths for removal of lighter or heavier ferrous metals.

Drop Down Gutter Brooms

Allows for the gutter brooms to "drop down" in front of the pick-up head so the metal bristles can scrub up extremely packed on material. Also allows very tight sweeping of curb lines to minimize amount of dust being kicked up before it is swept by the pick-up head.

CNG

In our continuing commitment to environmentally conscious sweeping, TYMCO offers a CNG (Compressed Natural Gas alternative fuel option for the Model 500x. The Model 500x CNG option is available as a Dedicated Unit, where both the sweeper and the truck chassis are CNG powered.

Pick-Up Head Curtain Lifter

Hydraulic actuated and retractable roller assembly that provides the pick-up head with the ability to sweep large volume of light debris. Electronically controlled in cab.

Street Sweeping & The Environment

The Model 500x has several environmental benefits, features, and options including:

- Doing More With Less

- Water Efficiency

- South Coast AQMD Rule 1186 Certification

- Compressed Natural Gas (CNG)

Photo Gallery

Model 500x® Regenerative Air Sweeper®

Diesel Auxiliary Engine / Diesel Conventional Cab Chassis

Download PDFSweeper Auxiliary Engine

- Engine - John Deere, 4045 turbo FT4, 4 cyl.

- Displacement - 275 in3 (4.5 L)

- Power - 115 hp (86 kW) @ 2200 RPM

- Net torque - 373 lb-ft @ 1500 RPM (506 Nm)

- Air cleaner - Heavy duty, w/pre-cleaner, and in-cab air restriction indicator w/gauge.

- Oil filter - Spin on, full flow

- Auxiliary engine fuel tank shared with chassis engine

- Diesel fuel tank capacity - 50 gal (189 L)

-

DEF tank - Dedicated

- Capacity (volumetric) - 5.4 gal (20.6 L)

- Capacity (useable) - 3.8 gal (14.4 L)

- Auxiliary engine protection system

- Fuel/water separator and separate fuel filter

- Open crankcase ventilation (OCV) filter

Blower, Rubber Lined

- Aluminum alloy, high volume, open face turbine

- Bearings - (2) sealed lifetime lube, anti-friction

- Housing - Isolation mounted, steel with abrasion resistant, replaceable liner

- Housing seal - Heavy rubber section, non-wiping, spring actuated Tilt-N-Seal® design

- Drive - Fixed displacement, heavy duty, bent axis hydraulic motor

Dust Separator

- Type - Cyclonic, multipass, centrifugal separation

- Size - 28 x 48 in (711 x 1219 mm)

- Location - Inside hopper

- Particulate removal achieved through dual skimmer slots into hopper

- Abrasion resistant housing w/replaceable liner

- Self-opening, self-emptying when hopper tilts

Hopper, Stainless Steel

- Volumetric capacity - 5.7 yd3 (4.3 m3)

- Useable capacity - 4.0 yd3 (3.06 m3)

- Construction - Welded non-magnetic stainless steel plate w/integral stiffeners

- Floor dump angle - 50°

- Dump door opening - 68 x 57 in (1727 x 1448 mm)

- Dump door - Self-locking

- Chute - 72 x 48 in (183 x 122 cm) stainless steel lined

- Chute reach - 22 in (56 cm) w/o side shift

- Dumping direction - Right side

- Lifting method - Two stage scissor lift, dual hydraulic cylinders w/integral holding valves

- Lift capacity - 10,000 lbs (4536 kg)

-

Dump height - Variable

- Minimum - 24 in (610 mm) from bottom of chute to ground

- Maximum - 132 in (11 ft) (3353 mm) from bottom of chute to ground

- Overall - 262 in (21 ft 8 in) (6655 mm)

- Dump tilt slope - 50°

- Hopper screen - 2 piece stainless steel screen w/ access for cleaning top side

- Hopper drain system

Broom Assist Pick-Up Head (BAH®)

- Type - Dual chamber with broom assist

- Width - 87 in (2210 mm)

- Pick-up head area - 3567 in2 (2.3 m2)

- Broom - 12 x 79 in (305 x 2007 mm) enclosed in rear of pick-up head

- Suspension - 4 springs 2 drag links

- Suction hose - 12 in diameter (305 mm)

- Pressure hose - 14 in diameter (356 mm)

- Skids - DUO SKID®, long-life carbide

- Pressure bleeder - Integral for leaf/light material pick-up.

- Reverse pick-up head system

Gutter Brooms, Twin, Patented

- Includes LED floodlight and parabolic mirrors

- Drive - Variable speed non-reversible hydraulic motor

- Adjustment - Adjustable for down pressure, pattern and wear

- Down pressure - Automatically adjusts to requirement

- Flexibility - All directions, integral anti-damage “swing away” relief valve

- Brooms - 43 in dia. (1.1 m) steel wire, vertical diggers

- Hydraulic tilt - Twin gutter brooms adjust for curb depth

Hydraulic System

- Drive - Direct drive

- Blower pump - Heavy duty variable displacement piston pump, hydrostatically drives blower

- Sweeper pump - Variable displacement piston pump, operates gutter brooms, pick-up head, stabilizers, hopper lift, hopper dump, and hopper door.

- Blower pump flow rate - 26 GPM (100 LPM)

- Sweeper pump flow rate - 11 GPM (42 LPM)

- BAH pump - Gear pump, operates Broom Assist Head broom motor

- BAH pump flow rate - 8 GPM (30 LPM)

- Reservoir - 34 gal (129 L)

- Return filter - 3 micron absolute, spin-on, in-line return

- Charge loop filter - 10 micron

- Vent filter - 10 micron spin-on

- Cooler - Air to oil integral with auxiliary engine heat exchanger

- Hydraulic level/temperature shutdown system

- Hydraulic oil filter restriction indicator - in cab

- Hydraulic oil sight/temperature gauge

- Auxiliary hydraulic system

Dust Control System

- Water spray nozzles for dust suppression

- Pump - Electric diaphragm

- Reservoir - Polyethylene 250 gallon (946 L)

- Filter - 80 mesh stainless steel, in-line

- Low water shut-off - Safety shut-off with audible and visual indicator in cab

-

Spray nozzles:

- Pick-up head - 4

- Gutter brooms (each) - 2

- Hopper - 1

- Hydrant fill hose w/storage area - 20 ft (6 m)

Control System

-

BlueLogic® Control System

Multiplexed electrical system includes hardware and TYMCO designed software that integrates the in-cab controls to the auxiliary engine and all sweeper functions; as well as provides intelligent safety features and on-board diagnostics (OBD) for the auxiliary engine and sweeper through the BlueLogic display. -

BlueLogic Display

Pedestal mounted touchscreen display provides sweeper and auxiliary engine data to the operator and includes hour meters (trip and total) for the auxiliary engine, gutter brooms, pick-up head, blower, water pump, and BAH broom; dump cycle counter, sweeper odometer (records curb miles swept and sweeping hours), service reminders, custom reminders, overspeed warning, low water audible alarm, dust control system winterization guide, and OBD. -

Interior Components

Leaf pressure bleeder control, BlueLogic display, auxiliary fuse panel, illuminated control switches: pick-up head, gutter brooms, blower RPM, dump cycle, variable speed gutter brooms, dust control water system nozzles, safety lights. -

Exterior Components

BlueLogic Control Modules (BCMs)

Storage Compartment

- Location - Rear left, beneath auxiliary engine

- Dimensions - 18 x 18 x 30 in (457 x 457 x 762 mm)

Safety/Warning Devices

- BlueLogic Control System utilizes solid-state proximity switches to help provide several safety systems: Right and left stabilizers automatically deploy before raising the hopper and retract after lowering the hopper, stabilizers down warning system, transmission interlock when stabilizers are down, blower actuation interlock, and minimum dump interlock. Other devices include alternating LED rear flashers, front mounted SAE Class 1/California Title 13 amber beacon light (LED) w/limb guard, rear view camera system, back-up alarm, scissor lift safety props, dump door/tilt cylinder safety props, and shop prop.

Optional Equipment

- AOD water pump w/washdown hose/gun

- Abrasion protection package

- Additional camera views - pick-up head, left gutter broom, right gutter broom

- Auto Sweep Interrupt (ASI)

- Auxiliary hand hose, 8 in (203 mm) diameter

- Gutter broom, drop down

- High output water system

- Hi/Low pressure washdown system

- Hopper load indicator alarms

- Hopper vibrator - electric

- Linear actuator, pressure bleeder w/gauge

- Low emissions package (required for South Coast AQMD Rule 1186)

- Magnet, light, standard, or heavy duty

- Pick-up head front curtain lifter

- Shop air purge, dust control system

- Sweeper deluge system, includes hopper and pick-up head deluge w/6 in (152 mm) cleanout port

- Screen vibrator - pneumatic

- Paint color (other than TYMCO standard white)

Special options are available for your individual requirements. Contact your local dealer or TYMCO.

Chassis Available

- International MV607

- Freightliner M2-106

Updated: 03/24/2022

Diesel Auxiliary Engine / Diesel Cabover Chassis

Download PDFSweeper Auxiliary Engine

- Engine - John Deere, 4045 turbo FT4, 4 cyl.

- Displacement - 275 in3 (4.5 L)

- Power - 115 hp (86 kW) @ 2200 RPM

- Net torque - 373 lb-ft @ 1500 RPM (506 Nm)

- Air cleaner - Heavy duty, w/pre-cleaner, and in-cab air restriction indicator w/gauge.

- Oil filter - Spin on, full flow

- Auxiliary engine fuel tank shared with chassis engine

- Diesel fuel tank capacity - 50 gal (189 L)

-

DEF tank - Dedicated

- Capacity (volumetric) - 5.4 gal (20.6 L)

- Capacity (useable) - 3.8 gal (14.4 L)

- Auxiliary engine protection system

- Fuel/water separator and separate fuel filter

- Open crankcase ventilation (OCV) filter

Blower, Rubber Lined

- Aluminum alloy, high volume, open face turbine

- Bearings - (2) sealed lifetime lube, anti-friction

- Housing - Isolation mounted, steel with abrasion resistant, replaceable liner

- Housing seal - Heavy rubber section, non-wiping, spring actuated Tilt-N-Seal® design

- Drive - Fixed displacement, heavy duty, bent axis hydraulic motor

Dust Separator

- Type - Cyclonic, multipass, centrifugal separation

- Size - 28 x 48 in (711 x 1219 mm)

- Location - Inside hopper

- Particulate removal achieved through dual skimmer slots into hopper

- Abrasion resistant housing w/replaceable liner

- Self-opening, self-emptying when hopper tilts

Hopper, Stainless Steel

- Volumetric capacity - 5.7 yd3 (4.3 m3)

- Useable capacity - 4.0 yd3 (3.06 m3)

- Construction - Welded non-magnetic stainless steel plate w/integral stiffeners

- Floor dump angle - 50°

- Dump door opening - 68 x 57 in (1727 x 1448 mm)

- Dump door - Self-locking

- Chute - 72 x 48 in (183 x 122 cm) stainless steel lined

- Chute reach - 22 in (56 cm) w/o side shift

- Dumping direction - Right side

- Lifting method - Two stage scissor lift, dual hydraulic cylinders w/integral holding valves

- Lift capacity - 10,000 lbs (4536 kg)

-

Dump height - Variable

- Minimum - 24 in (610 mm) from bottom of chute to ground

- Maximum - 132 in (11 ft) (3353 mm) from bottom of chute to ground

- Overall - 262 in (21 ft 8 in) (6655 mm)

- Dump tilt slope - 50°

- Hopper screen - 2 piece stainless steel screen w/ access for cleaning top side

- Hopper drain system

Broom Assist Pick-Up Head (BAH®)

- Type - Dual chamber with broom assist

- Width - 87 in (2210 mm)

- Pick-up head area - 3567 in2 (2.3 m2)

- Broom - 12 x 79 in (305 x 2007 mm) enclosed in rear of pick-up head

- Suspension - 4 springs 2 drag links

- Suction hose - 12 in diameter (305 mm)

- Pressure hose - 14 in diameter (356 mm)

- Skids - DUO SKID®, long-life carbide

- Pressure bleeder - Integral for leaf/light material pick-up.

- Linear actuator - pressure bleeder w/gauge - Integral for leaf/light material pickup

- Reverse pick-up head system

Gutter Brooms, Twin, Patented

- Includes LED floodlights and parabolic mirrors

- Drive - Variable speed non-reversible hydraulic motor

- Adjustment - Adjustable for down pressure, pattern and wear

- Down pressure - Automatically adjusts to requirement

- Flexibility - All directions, integral anti-damage “swing away” relief valve

- Brooms - 43 in dia. (1.1 m) steel wire, vertical diggers

- Hydraulic tilt - Gutter brooms adjust for curb depth

Hydraulic System

- Drive - Direct drive

- Blower pump - Heavy duty variable displacement piston pump, hydrostatically drives blower

- Sweeper pump - Variable displacement piston pump, operates gutter brooms, pick-up head, stabilizers, hopper lift, hopper dump, and hopper door.

- Blower pump flow rate - 26 GPM (100 LPM)

- Sweeper pump flow rate - 11 GPM (42 LPM)

- BAH pump - Gear pump, operates Broom Assist Head broom motor

- BAH pump flow rate - 8 GPM (30 LPM)

- Reservoir - 34 gal (129 L)

- Return filter - 3 micron absolute, spin-on, in-line return

- Charge loop filter - 10 micron

- Vent filter - 10 micron spin-on

- Cooler - Air to oil integral with auxiliary engine heat exchanger

- Hydraulic level/temperature shutdown system

- Hydraulic oil filter restriction indicator - in cab

- Hydraulic oil sight/temperature gauge

- Auxiliary hydraulic system

Dust Control System

- Water spray nozzles for dust suppression

- Pump - Electric diaphragm

- Reservoir - Polyethylene 360 gallon (1362 L)

- Filter - 80 mesh stainless steel, in-line

- Low water shut-off - Safety shut-off with audible and visual indicator in cab

-

Spray nozzles:

- Pick-up head - 4

- Gutter brooms (each) - 2

- Hopper - 1

- Hydrant fill hose w/storage area - 20 ft (6 m)

Control System

-

BlueLogic® Control System

Multiplexed electrical system includes hardware and TYMCO designed software that integrates the in-cab controls to the auxiliary engine and all sweeper functions; as well as provides intelligent safety features and on-board diagnostics (OBD) for the auxiliary engine and sweeper through the BlueLogic display. -

BlueLogic Display

Pedestal mounted touchscreen display provides sweeper and auxiliary engine data to the operator and includes hour meters (trip and total) for the auxiliary engine, gutter brooms, pick-up head, blower, water pump, and BAH broom; dump cycle counter, sweeper odometer (records curb miles swept and sweeping hours), service reminders, custom reminders, overspeed warning, low water audible alarm, dust control system winterization guide, and OBD. -

Interior Components

BlueLogic display, auxiliary fuse panel, illuminated control switches: pick-up head, gutter brooms, blower RPM, leaf pressure bleeder, dump cycle, variable speed gutter brooms, dust control water system nozzles, safety lights. -

Exterior Components

BlueLogic Control Modules (BCMs)

Storage Compartment

- Location - Rear left, beneath auxiliary engine

- Dimensions - 18 x 18 x 30 in (457 x 457 x 762 mm)

Safety/Warning Devices

- BlueLogic Control System utilizes solid-state proximity switches to help provide several safety systems: Right and left stabilizers automatically deploy before raising the hopper and retract after lowering the hopper, stabilizers down warning system, transmission interlock when stabilizers are down, blower actuation interlock, and minimum dump interlock. Other devices include alternating LED rear flashers, front mounted SAE Class 1/California Title 13 amber beacon light (LED) w/limb guard, rear view camera system, back-up alarm, scissor lift safety props, dump door/tilt cylinder safety props, and shop prop.

Optional Equipment

- AOD water pump w/washdown hose/gun

- Abrasion protection package

- Additional camera views - pick-up head, left gutter broom, right gutter broom

- Auto Sweep Interrupt (ASI)

- Auxiliary hand hose, 8 in (203 mm) diameter

- Gutter broom, drop down

- High output water system

- Hi/Low pressure washdown system

- Hopper load indicator alarms

- Hopper vibrator - electric

- Linear actuator, pressure bleeder w/gauge

- Low emissions package (required for South Coast AQMD Rule 1186)

- Magnet, light, standard, or heavy duty

- Pick-up head front curtain lifter

- Shop air purge, dust control system

- Sweeper deluge system, includes hopper and pick-up head deluge w/6 in (152 mm) cleanout port

- Screen vibrator - pneumatic

- Paint color (other than TYMCO standard white)

- Special options are available for your individual requirements. Contact your local dealer or TYMCO.

Special options are available for your individual requirements. Contact your local dealer or TYMCO.

Chassis Available

- Peterbilt 220

Updated: 03/24/2022

CNG Auxiliary Engine / CNG Conventional Cab Chassis

Download PDFSweeper Auxiliary Engine

- Engine - KEM/GM Vortec 5700 CNG

- Displacement - 350 in3 (5.7 L)

- Power - 136 HP (101 kW)@ 2650 RPM

- Net torque - 284 lb-ft (385 Nm) @ 2100 RPM

- Air cleaner - Heavy duty, w/pre-cleaner, and in-cab air restriction indicator w/gauge.

- Oil filter - Remote mount, spin on, full flow

- Auxiliary engine fuel rack shared with chassis engine

- CNG fuel rack capacity - 60 DGE (227 DLE)

- Auxiliary engine shutdown system

- Remote engine oil cooler

Blower, Rubber Lined

- Aluminum alloy, high volume, open face turbine

- Bearings - (2) sealed lifetime lube, anti-friction

- Housing - Isolation mounted, steel with abrasion resistant, replaceable liner

- Housing seal - Heavy rubber section, non-wiping, spring actuated Tilt-N-Seal™ design

- Drive - Fixed displacement, heavy duty, hydraulic motor

Dust Separator

- Type - Cyclonic, multipass, centrifugal separation

- Size - 28 x 48 in (711 x 1219 mm)

- Location - Inside hopper

- Particulate removal achieved through dual skimmer slots into hopper

- Housing - Abrasion resistant, replaceable liner

- Self-opening, self-emptying when hopper tilts

Hopper, Stainless Steel

- Volumetric Capacity - 5.7 yd3 (4.3m3)

- Usable Capacity - 4.0 yd3 (3.06m3)

- Construction - Welded non-magnetic stainless steel plate w/integral stiffeners

- Floor dump angle - 50°

- Dump door opening - 68 x 57 in (1727 x 1448 mm)

- Dump door - Self-locking

- Chute - 72 x 48 in (183 x 122 cm) stainless steel lined

- Chute reach - 22 in (56cm) w/o side shift

- Dumping direction - Right side

- Lifting method - Two stage scissor lift, dual hydraulic cylinders w/integral holding valves

- Lift capacity - 10,000 lbs. (4536 kg)

-

Dump height - Variable

- Minimum - 24 in (610 mm) from bottom of chute to ground

- Maximum - 132 in (11 ft) (3353 mm) from bottom of chute to ground

- Overall - 262 in (21 ft 8 in) (6655 mm)

- Dump tilt slope - 50°

Broom Assist Pick-Up Head (BAH®)

- Type - Dual chamber with broom assist

- Width - 87 in (2210 mm)

- Pick-up head area - 3567 in2 (2.3 m2)

- Broom - 12 x 79 in (305 x 2007 mm) enclosed in rear of pick-up head

- Suspension - 4 springs 2 drag links

- Suction hose - 12 in diameter (305 mm)

- Pressure hose - 14 in diameter (356 mm)

- Skids - DUO SKID®, long-life carbide

- Pressure bleeder - Integral for leaf/light material pick-up.

- Reverse pick-up head system

Gutter Brooms, Twin, Patented

- Includes LED floodlights and parabolic mirrors

- Drive - Variable speed non-reversible hydraulic motor

- Adjustment - Adjustable for down pressure, pattern and wear

- Down pressure - Automatically adjusts to requirement

- Flexibility - All directions, integral anti-damage "swing away" relief valve

- Brooms - 43 in dia. (1.1 m) steel wire, vertical diggers

- Hydraulic tilt - Twin gutter brooms adjust for curb depth

Hydraulic System

- Drive - Direct drive

- Blower pump - Heavy duty variable displacement piston pump, hydrostatically drives blower

- Sweeper pump - Variable displacement piston pump, operates gutter brooms, pick-up head, stabilizers, hopper lift, hopper dump, and hopper door.

- Blower pump flow rate - 26 GPM (100 LPM)

- Sweeper pump flow rate - 11 GPM (42 LPM)

- BAH pump - Gear pump, operates Broom Assist Head broom motor

- BAH pump flow rate - 8 GPM (30 LPM)

- Reservoir - 34 gal (129 L)

- Return filter - 3 micron absolute, spin-on, in-line return

- Charge loop filter - 10 micron

- Vent Filter- 10 micron spin-on

- Cooler - Air to oil

- Hydraulic level/temperature shutdown system

- Hydraulic oil filter restriction indicator - in cab

- Hydraulic oil sight/temperature gauge

- Auxiliary hydraulic system

Dust Control System

- Water spray nozzles for dust suppression

- Pump - Electric diaphragm

- Reservoir - Polyethylene 250 gallon (946 L)

- Filter - 80 mesh stainless steel, in-line

- Low water shut-off - Safety shut-off with audible and visual indicator in cab

-

Spray nozzles

- Pick-up head - 4

- Gutter brooms (each) - 2

- Hopper - 1

Control System

-

BlueLogic® Control System

Multiplexed electrical system includes hardware and TYMCO designed software that integrates the in-cab controls to the auxiliary engine and all sweeper functions; as well as provides intelligent safety features and on-board diagnostics (OBD) for the auxiliary engine and sweeper through the BlueLogic display. -

BlueLogic Display

Pedestal mounted touchscreen display provides sweeper and auxiliary engine data to the operator and includes hour meters (trip and total) for the auxiliary engine, gutter brooms, pick-up head, blower, water pump, and BAH broom if applicable; dump cycle counter, sweeper odometer (records curb miles swept and sweeping hours), service reminders, custom reminders, overspeed warning, low water audible alarm, dust control system winterization guide, and OBD. -

Interior Components

Leaf pressure bleeder control, BlueLogic display, auxiliary fuse panel, illuminated control switches: pick-up head, gutter brooms, blower RPM, dump cycle, variable speed gutter brooms, dust control water system nozzles, safety lights. -

Exterior Components

BlueLogic Control Modules (BCMs)

Storage Equipment

- Location - Rear left, beneath auxiliary engine

- Dimensions - 18 x 18 x 30 in (457 x 457 x 762 mm)

Safety/Warning Devices

- BlueLogic Control System utilizes solid-state proximity switches to help provide several safety systems: Right and left stabilizers automatically deploy before raising the hopper and retract after lowering the hopper, stabilizers down warning system, transmission interlock when stabilizers are down, blower actuation interlock, and minimum dump interlock. Other devices include alternating LED rear flashers, front mounted SAE Class 1/California Title 13 amber beacon light (LED) w/limb guard, rear view camera system, back-up alarm, scissor lift safety props, dump/tilt cylinder safety props, and shop prop.

Optional Equipment

- AOD water pump w/washdown hose/gun

- Abrasion protection package

- Additional camera views - pick-up head, left gutter broom, right gutter broom

- Auto Sweep Interrupt (ASI)

- Auxiliary hand hose, 8 in (203 mm) diameter

- Gutter broom, drop down

- High output water system

- Hopper load indicator alarms

- Hopper vibrator - electric

- Linear actuator, pressure bleeder w/gauge

- Low emissions package (required for South Coast AQMD Rule 1186)

- Magnet, light, standard, or heavy duty

- Pick-up head front curtain lifter

- Shop air purge, dust control system

- Sweeper deluge system, includes hopper and pick-up head deluge w/6 in (152 mm) cleanout port

- Sweeper odometer

- Screen vibrator - pneumatic

- Paint color (other than TYMCO standard white)

Special options are available for your individual requirements. Contact your local dealer or TYMCO.

Chassis Available

- Freightliner M2-112 CNG

Updated: 03/24/2022